Aluminum Alloy Wheel Series Products

Lizhong owns four main production technologies:low pressure casting, flow forming, solid forging and liquid forging, with more than 400 varieties and more than 2000 specifications and models of products, ensuring the outstanding market competitiveness.

- Low Pressure Casting Wheels

- Low Pressure Casting Wheels

- Liquid Forged Wheels:

- Solid Forged Wheels

widely used in economic and high-grade passenger cars, product features: economic and practical.

widely used in economic and high-grade passenger cars, product features: economic and practical.

mainly used for commercial vehicles, product features: high strength, stable performance.

mainly used for high-end passenger cars, racing cars, trucks, buses, etc. Product features: excellent performance, light weight, higher quality.

-

-

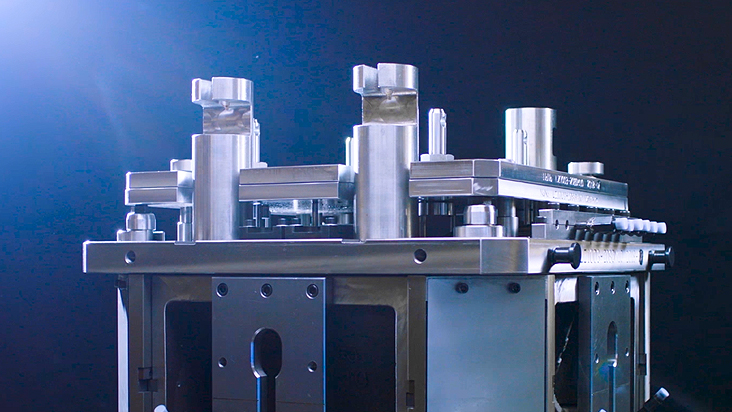

Molds

-

Lizhong's current mold production capacity is 1200 sets/year.

Mold is one of the key technologies in the manufacturing of aluminum alloy wheel. Mold technology directly influences the quality and production efficiency of wheels. Advanced mold R & D and manufacturing capacity is an important part of the core competitiveness of Lizhong.

-

-

-

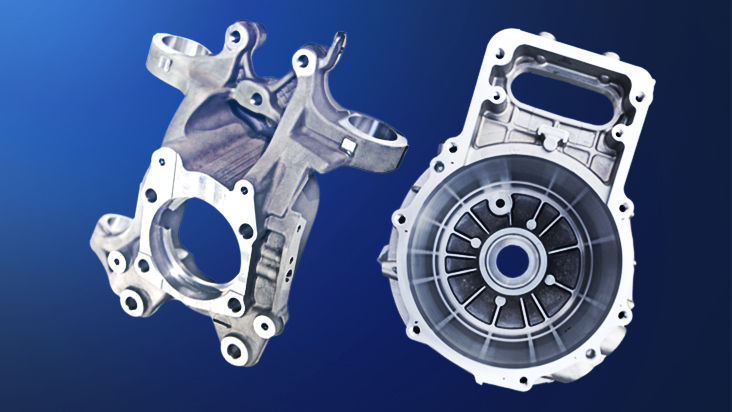

Lightweight auto parts series

-

Lizhong currently produces 2 million pieces of steering knuckle, chassis suspension parts and motor housing per year. Lightweight and complete aluminization are key technologies for fuel vehicle energy saving, emission reduction and new energy vehicle endurance improvement. Ultra-lightweight auto parts products will be our key development direction. Taking full advantage of the market synergy of Lizhong Wheels, it has quickly become a new business growth point for Lizhong Wheel Group.

-