| LZHM-01(AISi7MnMg) |

Invention Patent 201510960833.7 |

Balanced strength and toughness with comprehensive performances. |

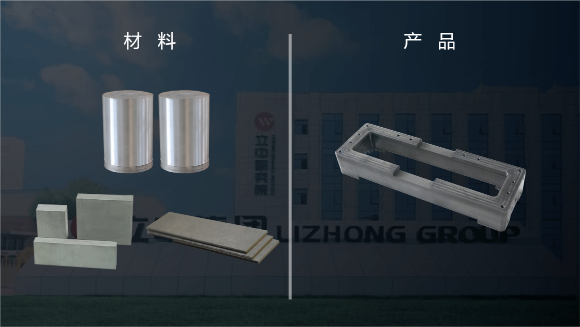

GIGA-Casting non-heat-treatment structural components. |

Large-scale integrated aluminum alloy structural component of EVs, such as rear floor, front engine compartments, battery trays, etc. |

| LDHM-02(AISi9MnMoZr) |

Invention Patent 202010018461.7 |

Optimal Strength-toughness balance, superior thermal Stability, excellent cast ability, Low casting temperature & extended mold life. |

High-pressure casting for GIGA-Casted structural components. |

Large-scale integrated aluminum alloy structural component of EVs, such as rear floor, front engine compartments, battery trays, etc. |

| LZHM-03(AISi8MnMgCu) |

Invention Patent 202311414034.0 |

Superior strength-toughness balance with high impurity tolerance, allowing for low-carbon, cost-efficient production. |

High-pressure casting for GIGA-Casted structural components. |

Large-scale integrated aluminum alloy structural component of EVs, such as rear floor, front engine compartments, battery trays, etc. |

| LZHM-04(AISi8MnZnMg) |

Invention Patent 202310894260.7 |

Superior strength-toughness balance with high impurity tolerance, allowing for low-carbon, cost-efficient production.

Low cooling-rate sensitivity ensures same properties across different sections of large-scale structural castings. |

High-pressure /low-pressure casting for GIGA-Casted structural components |

Large-scale integrated aluminum alloy structural component of EVs, such as rear floor, front engine compartments, battery trays, etc. |

| LZHM-05(AISi9MnMgCu) |

Invention Patent 202510479750.X |

Excellent comprehensive properties and a good strength-toughness balance;especially, superior strength that outperforms other heat-treatment-free aluminum alloys.

With high impurity tolerance, allowing for low-carbon, cost-efficient production. |

High-pressure casting for GIGA-Casted structural components. |

Large-scale integrated aluminum alloy structural component of EVs, such as monocoque bodies, rear floor, front engine compartments, battery trays, etc. |

| LZHM-06(AIMg5Si2Mn) |

-- |

The Al-Mg series heat-treatment-free aluminum alloy offers superior strength and toughness compared to the Al-Si series. |

High-pressure casting of structural components with higher strength requirements. |

Aluminum alloy structural component, such as sub-frames, front cabin triangular beams, large battery packs, etc. |

| LZHM-07(AIMg6Si3Mn) |

-- |

The Al-Mg series heat-treatment-free aluminum alloy offers superior strength and toughness compared to the Al-Si series. AIMg6Si3Mn has a higher YS than AIMg5Si2Mn. |

High-pressure casting of structural components with higher strength requirements. |

Aluminum alloy structural components such as, sub-frames, battery packs, front cabin triangular beams, etc. |

| LZHM-08(AISi9Cu2Mg1Mn) |

-- |

It has a higher TS、YS、EL than A380 in different heat-treatment states |

High-pressure casting for GIGA-Casted structural components |

High-strength parts in EVs, humanoid robot, UAVs. |

CN

CN

EN

EN

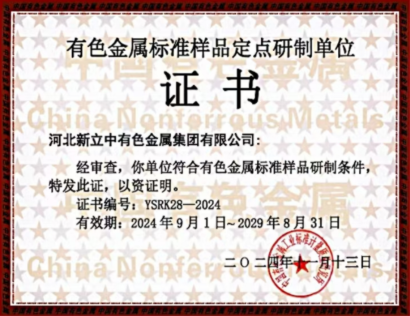

Lizhong Sitong New Materials

Lizhong Sitong New Materials